This is an era of technology and everyone relies on technology. Technology has changed mankind a lot. Technology has the immense effect on mankind. It has basically given birth to new mankind in which men just have to design certain tools or devices for their work and then command them to work accordingly

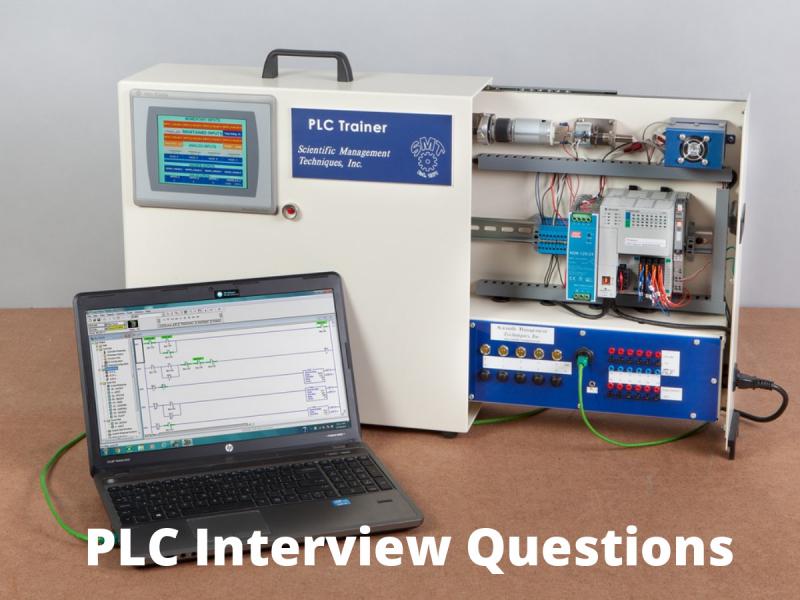

One such device, which has the immense effect and is based on logical technology in the field of different industries, is PLC. PLC is abbreviated form of Programmable Logic Controller or Programmable Controller. It is a type of computer.

But it is not an ordinary computer; it is a digital computer which has been designed especially for industries which deal with the manufacture of assembly lines for video games, automobile devices etc. and for designing certain devices which are used to manufacture robots and has easy programming and diagnosis.

For the first time, they were developed and used by an automobile industry in order to provide flexible, simple and easily programmable controls which could replace the hard and complex computers, sequencers and timers.

Read Common PLC Interview Questions